CCX3-2( CCX) series intensive bus duct

Download: bus duct

- Product Description

-

Product Overview

CCX3-2(CCX) Series Intensive Bus Duct System is a flexible and reliable power distribution equipment. Its complete branch unit and detailed CAD site three-dimensional trend design scheme can enable you to obtain an optimized power transmission solution to meet your special design requirements at the engineering site.

-Reasonable structure and quick installation;

-A unique structural design enables the bus system to have super anti-short circuit capability and eliminate trunk harmonics.

-The bus has a small overall volume and various flexible functional units.

-No matter whether it is horizontal vertical installation, horizontal installation or vertical installation of shaft, it has a stable installation plane, and the current carrying capacity is not affected by any

installation form.Structural Features

CCX3-2( CCX) series bus duct adopts reasonable "sandwich" phase line close lamination structure design, which makes the bus duct more compact in appearance and smaller in volume, enhances the dynamic and thermal stability of the bus system, makes the bus have the advantage of low impedance voltage reduction, and prevents the formation of "chimney effect" of bus duct in case of fire.

All-aluminum shell

1. Integral aluminum alloy side plate structure, the conductor is wrapped in the metal side plate, completely preventing the penetration of water vapor and the intrusion of harmful dust. Make the overall protection level of the bus reach real IP54 protection;

2, special aluminum shell, forming a non-magnetic choke coil, can reduce the transmission of high-current bus interphase eddy current, reduce the passage of main busbar harmonic current, reduce the heating phenomenon caused by the above reasons, reduce the voltage drop of long-distance transmission, and significantly enhance the current-carrying capacity of busbar;

3. The aluminum side plate structure with integral close contact with the conductor can be straight from the side plate, cover plate and other elevations. Transmit and dissipate heat, improve the heat dissipation capacity of the bus system and increase the current carrying capacity;

4, an integral grounding system is formed within the scope of the shell. The user can choose this integral aluminum housing with> 50% line capacity as the ground conductor. In the event of a large-capacity ground short-circuit fault, the short-circuit current can be effectively transmitted through the large-section aluminum metal shell to protect the safe operation of the entire bus duct system and the safety of the operator.

joint assembly

adopts two forms: one is common type, with insulating bolt locking design; The other adopts the current international advanced single-arm bolt locking design, that is, only one side of the torque wrench device is required to lock the high-strength bolts without other auxiliary tools. For details, please refer to the specified torque values of bolts of various specifications. The connector can also be equipped with a single-arm double-headed torque bolt. When the locking torque reaches a fixed value, one end of the bolt will automatically fall off, and the other bolt head is reserved for future maintenance or assembly and disassembly. Torque wrench is not required during operation. The reasonable structural design of

connector can easily insert each unit of the bus from above. The large-area ball washer inside the pressure plate on both sides makes the contact surface pressure inside the whole joint uniform, prevents vibration, and achieves stable electrical communication in various environments of the whole device. Each of the same specifications of the connector are interchangeable, so that the bus system in the installation of flexible use.

Technical Parameters

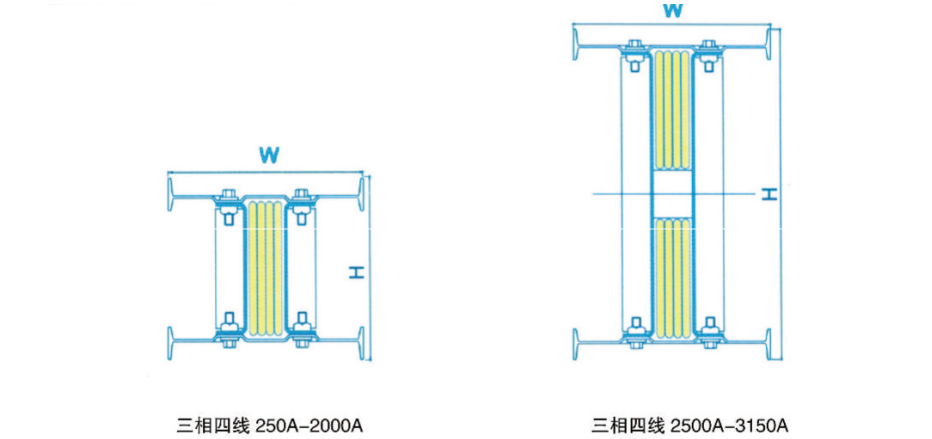

1.CCX3- 2( CCX) Busway Frequency is 50-60Hz, Rated Current 250A-3150A, Rated Insulation Voltage Below 1000V Three-Phase Four-Phase Five-Wire Power Supply and Distribution Equipment.

2, bus duct can withstand 50Hz ,3750V test voltage for 1mln without breakdown or flashover.

3. When the bus passes the rated working current for a long time, the temperature rise of any conductor shall not exceed 60K.

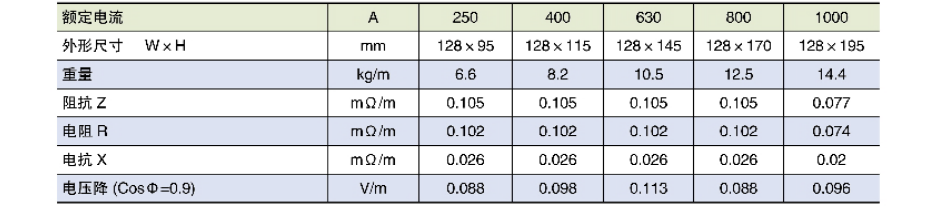

4, bus duct current and performance table:

250A- 1000A

1250A-31 50A

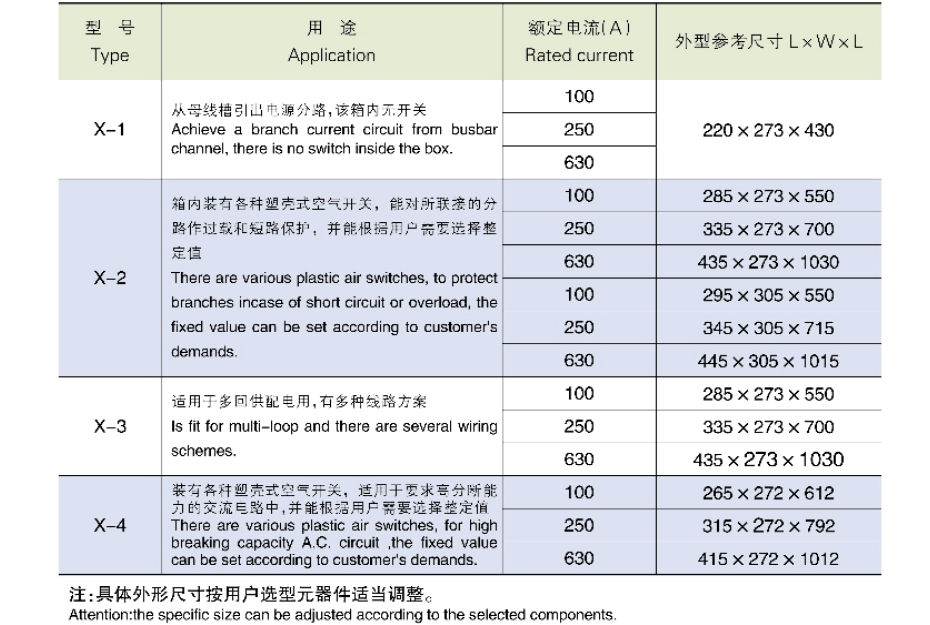

Plug-in Box Outline Reference Dimension

Bus Branch Plug-in Box

Tap-off Box

Economical Door Opening Operation

Outside Operation

Electric Remote Operation

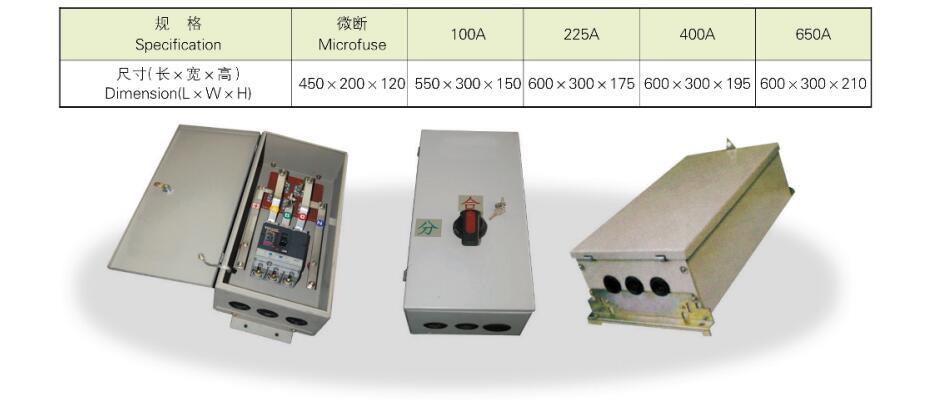

Current Specification: 100A, 250A, 400A, 630A

switches can be configured according to the user's selection of

plug box size

Previous Page

Next Page

Product inquiry